A chisel is a tool used for cutting, chopping, and shaping wood, stone, and metals. Chisels have sharp edges in a long metal blade and also it has a metal, wooden, or plastic handle. To crave, cutting or shape a material you can hit the back of the chisel with a hammer or mallet.

Chisels are the most commonly used hand tool in industries where wood, metal, and stonework is performed. Chisels will become blunt due to use. For efficiency in cutting or chipping the chisels are to be re-sharpened regularly. Chisels are specified according to their

- Length

- Width of the cutting edge

- Type

- Cross-section of the body.

What is chipping?

Chipping is an operation of removing excess metal with the help of a chisel and hammer.

Table of Contents

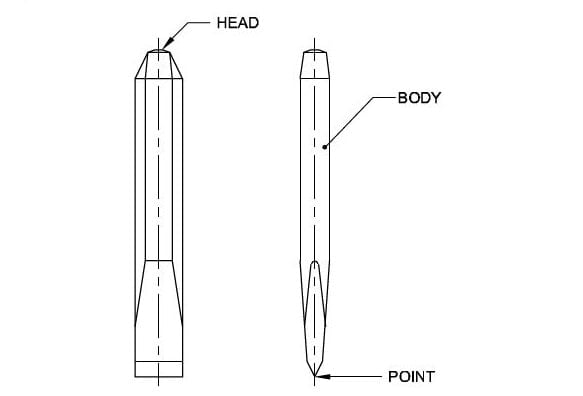

Parts of a Chisel:

A chisel has the following parts.

- Head

- Body

- Point or cutting edge.

Chisels are made from high carbon steel or chrome vanadium steel. The cross-section of chisels is usually hexagonal or octagonal. The cutting edge is hardened and tempered.

What is a cold chisel?

A cold chisel is a hand-cutting tool used for chopping and cutting-off operations. Cold chisels are made up of cast steel or high carbon steel, hardened and tempered and tempered at the cutting end. These contain 0.75% to 1% of carbon.

They are usually octagonal in cross-section. The cold chisels are made up of several types like cross-cut, half-round, and diamond point chisels, etc.

The cold chisel is used on cold metal. These chisels are mainly used for cutting mild steel. The cold chisel has one disadvantage that it tends to spread the metal being cut, particularly when this is sheet metal.

Basically cold chisels are used to cut heavy metals because of limited space. These chisels are available in four, six, or eight sides and the commonly used length is around 150mm.

What is a hot chisel?

Hot chisel is mainly used for cutting hot metals in a blacksmith’s workshop. A chisel has a hole in it where a wooden handle is attached and the cutting edge is formed at a 30° angle. During usage, you can frequently dip it into the water in order to make it cold, so that all edges are found to remain intact.

Types of chisels:

There are five common types of chisels.

- Flat chisel

- Cross-cut chisel

- Half-round nose chisel

- Diamond point chisel

- Web chisel.

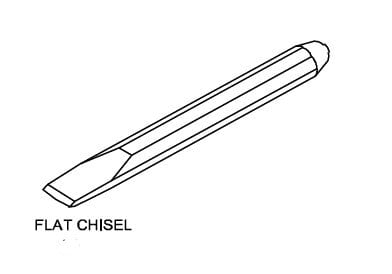

Flat chisels:

They are used to remove metal from large flat surfaces and chip-off excess metal of welded joints and castings.

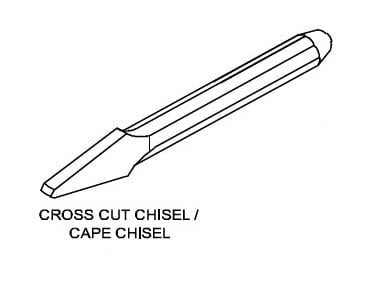

Cross-cut or cape chisels:

These are used for cutting keyways, grooves, and slots.

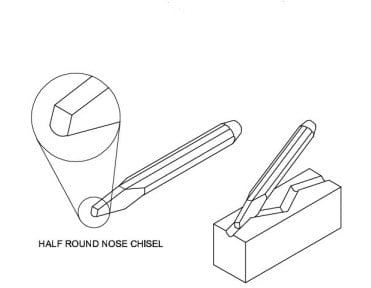

Half-round nose chisels:

They are used for cutting curved grooves (oil grooves).

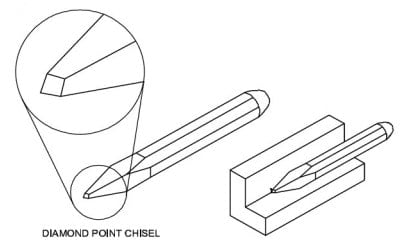

Diamond point chisels:

These are used for squaring materials at the corners, joints.

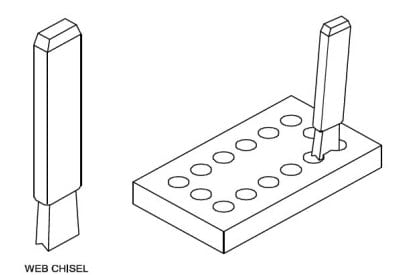

Web chisels/ punching chisels

These chisels are used for separating metals after chain drilling.

Angles of chisels:

Point angles and materials:

The correct point/cutting angle of the chisel depends on the material to be chipped. Sharp angles are given for soft materials and wide angles for hard materials. The correct point and angle of inclination generate the correct rake and clearance angles.

Rake angle:

The rake angle is the angle between the top face of the cutting point, and the normal (90°) to the work surface at the cutting edge.

Clearance angle:

Clearance angle is the angle between the bottom face of the point and the tangent to the work surface originating at the cutting edge.

If the clearance angle is too low or zero, the rake angle increases. The cutting edge cannot penetrate into the work. The chisel will slip. If the clearance angle is too great, the rake angle reduces. The cutting edge digs in and the cut will become deeper and deeper. The correct point angle and angle of inclination for different materials for chipping are given below.

| Material to be cut | Point angle |

| High carbon steel | 65 ° |

| Cast Iron | 60 ° |

| Mild steel | 55 ° |

| Brass | 50 ° |

| Copper | 45 ° |

| Aluminum | 30 ° |

What is crowning?

Crowning is a slight curvature is ground called “Crowning” to the cutting edge of the chisel, to prevent the digging of corners, which leads to breakage of the chisel point. “Crowning” allows the chisel to move freely along a straight line while chipping.

Chisel hazards:

- Eye injuries due to flying chips from tools,

- Puncture wounds and infections,

- Cut injuries due to sharp edges of chisels.

- Cutting of fingers, tendons and arteries etc.

Chisel safety precautions:

The main causes for these accidents are the use of unsuitable and damaged chisels.

- Chisels are must be made in good quality and they are must be in good condition. (Use only quality tools).

- Chisels are used only for the specific purposes for which they are designed.

- Wooden handles of chisels are the best quality and they are must be suitable shape and size.

- Chisels should be made of carefully selected steel, hard enough to withstand blows without mushrooming extensively but not so hard as to chip or break.

- When chisels are not in use, sharp-edged or sharp points must be protected with protection for the edges or points.

- Inspect the chisel before using it.

- No greasy subject on the head of the chisel.

- Apply oil to avoid rust.

- Chisels should be dressed periodically to avoid mushroom heads.

- Replace the chisel as soon as it begins to crack or mushroom. When a mushroomed head is pounced, there is a danger that the chips will be knocked off the damaged head and will fly into the eyes.

- Replaced or repaired when found defective.

- A cold chisel will buckle or bounce if it is not large or strong enough for the metal being cut.

- Wear safety glasses when chipping or shearing with a cold chisel. Protect the sharp edges of the chisel by storing them in a rack, workbench, or slotted section of a toolbox.

Faq’s for Chisel?

What is a chisel used for?

Chisels are used for cutting, carving, dressing, shaping metal, stones, or wood.

What is the use of mortise chisel?

Mortise chisels are specially designed chisels for chopping out mortise joints. They are designed strongly to withstand heavy blows with a mallet or hammer.

What is the use of a firmer chisel?

Basically, the firmer chisels are used in woodworking industries or workshops. It has a thick strong blade. These chisels are strong enough to withstand heavy blows with a mallet. Mostly firmer chisels are used by the carpenters. It removes the large pieces of wood in a single strike.

What is a cold chisel used for?

Cold chisels are mainly used for cutting mild steel or other metals. Cold chisels are easily cut metal screws, bolts, nails, and brackets, etc.