Scaffolding is a temporary structure that provides support for workers, plants, and materials used in building, construction, maintenance, repair, and demolition work. We need to follow scaffolding safety procedures. Scaffolding means a convenient platform for persons to work at height. Scaffolding shall be designed by a qualified and competent Engineer. Scaffoldings erection, alteration, and dismantling should be done under the supervision of a competent person.

Table of Contents

Scaffolding types

- Single Scaffolding

- Double Scaffolding

- Trestle Scaffolding

- Steel Scaffolding

- Suspended Scaffolding

- Patented Scaffolding

- Cantilever Scaffolding

- Mobile Scaffolding

- Kwikstage Scaffolding

Single Scaffolding

Single scaffolding is also called bricklayer scaffolding and is mostly employed in brick masonry. Single scaffolding consists of a single framework of standards, ledgers, putlogs, etc. They are corresponding to the wall at a distance of around 1.2 m. Distance between the Standards is 2 to 2.5 meters apart from each other. At a vertical interval of 1.2 to 1.5 interval ledgers are connected to standards. putlogs are set at a fixed distance of 1.2 to 1.5 meters and are extracted from a gap in the wall at the end of the ledger. This type of scaffold is only suitable for new work in bricks or blocks.

Double Scaffolding

Double Scaffolding is generally widely used for stone masonry works, therefore; it is also known as mason’s scaffolding. This scaffolding type is generally stronger and provides better support for construction works as compared to single scaffolding. In stone walls, it is tough to make holes in the wall for supporting putlogs so two rows of standards are separated by ledgers for better support and strength.

Basically, the first row is about 20 to 30 cm away from the wall, and the second one is 1m away from the first row. With the support of both frames then putlogs are positioned. Cross braces and rakers can also be added at a later stage to make the structure stronger.

Trestle Scaffolding

In Trestle scaffolding, the working platform is supported on tripod-type movable ladders with no standards, putlogs, etc. This is generally used work inside the room, such as paintings, minor repairs, etc and It is used up to a height of 5m. These types of scaffolding can be easily shifted from one place to another and mounted with wheels.

Steel Scaffolding

Steel scaffolding is constructed by steel tubes that are fixed together by steel couplers. It can be assembled or dismantled more quickly than others. The steel scaffolding structure provides It has greater strength, greater durability, and high fire resistance. Because of greater strength, it can be used for greater heights. Steel scaffoldings are more expensive and it requires more skilled labor and also needs repainting from time to time to keep their color and protect it from damage. but it provides more safety for workers. It is one of the most popular scaffolding widely used these days. It is mainly used for outdoor construction and bigger structures.

Suspended Scaffolding

In suspended scaffolding, two or more platforms are suspended by ropes, wires, or chains from overhead outriggers anchored to the building. Anchor plates should be tied with U bolts. Counterweights are used to prevent overturning. It can be raised or lowered to the required level. These scaffolding platforms can be moved vertically as well as horizontally when required. Suspended scaffolding is mainly used for different types of construction projects and maintenance jobs like paintings, repair works, window cleaning, etc. Overhead protection should be provided if the risk of falling objects is possible.

Patented Scaffolding

Patented scaffoldings are made up of steel these are ready-made scaffoldings that are available in the market. Patented scaffoldings are fitted with special couplings and frames etc. The working platform is set on brackets that are adjustable to the required height. These are easy to assemble and more convenient for short-term works such as repairs.

Cantilever Scaffolding

Cantilever scaffolding is also referred to as needle scaffolding because the needle supports the entire scaffold. It is Also known as, Single Frame Scaffolding. Cantilever Scaffolding has limited usage and requires various checks before the installation. Cantilever scaffolds are easy to erect and can support an average workman and supplies. In Cantilever scaffolding, standards are supported on a series of needles that are taken out through holes in the wall. When Workers working on cantilever scaffolding systems, they must be fitted with safety harnesses. Cantilever or needle scaffoldings are used under such conditions:

- The ground is weak or not capable to support the standards.

- When the ground is close to the wall and free from traffic.

- When construction or maintenance is required at the upper part of the wall.

Mobile Scaffolding

- The maximum height for mobile scaffolds shall be 9.6 M except that this may be increased to 12 M if it is tied to a structure when in use.

- When free-standing mobile scaffold towers are used, the height shall not exceed four times the minimum base dimension.

- Wheels or casters shall be properly designed for strength and dimensions to support four times the maximum intended load. All wheels shall be provided with a positive locking device to hold the scaffold in position.

- Scaffolds shall be braced by cross-bracing or diagonal braces or both, for securing vertical members together laterally, and the cross braces shall be of such length as will automatically square and align vertical members so that the erected scaffold always plumb, square and rigid. All brace connections shall be made square.

- The platform shall be tightly decked for the full width of the scaffold and scaffold boards shall be secured against displacement. Platforms shall be provided with a guard rail.

- The force necessary to move the mobile scaffold shall be applied near or as close to the base as possible and stabilize the tower during movement. Mobile scaffolds shall be moved on level floors, free from obstructions.

- The wheels or casters shall be provided with rubber or similar resilient tires.

- Workmen shall not be allowed to ride on mobile scaffolds.

- All material s shall be removed before the mobile scaffold is moved.

- The mobile scaffold in use shall rest upon a suitable footing and shall stand plumb. The casters or wheels shall be locked to prevent any movement.

- A mobile scaffold shall also conform to the applicable provisions of tube and coupler independent scaffolding.

Kwikstage Scaffolding

Kwikstage Scaffolding is commonly used nowadays due to its safety, reliability, and flexibility. The kwick-stage scaffold is actually is easy and simple to assemble. No need for specialized training to assemble this scaffolding. Kwikstage scaffold components can be used wherever a regular scaffold is used. This durable scaffolding product can be built to any height safely and easily with its patented interlocking system. The scaffold is constructed of several tubes assembled in a grid pattern. It is available in different materials such as timber, aluminum, and steel. It is the most durable, lightweight, and convenient scaffolding. They are also very suitable for builders, painters, renderers, and tradesmen who need access to any height easily and safely.

Erection of Scaffolding:

- Scaffold erection shall be carried out only by skilled workmen with the supervision of a competent supervisor.

- The scaffolding erection area shall be cordoned.

- Lifting of the frame and other parts of the scaffolding shall be carried out using Derrick and pulley arrangement.

- The ladder shall be used for climbing up and down.

- A red tag shall be provided to caution that the scaffold is under erection.

- At the end of the day, if a scaffold is going to be left half erected, it is essential to lower all the loose scaffold materials down and ensure that the scaffold is braced adequately to the building/structure.

- A double lanyard safety harness shall be used by all workmen engaged in scaffold erection work.

Dismantling of scaffolding:

- Scaffold dismantling area shall be cordoned and only skilled workmen shall be used for this purpose.

- The scaffold being dismantled shall be provided with a red tag to indicate it is unsafe to work on it.

- Dismantled materials shall be lowered using derrick and pulley arrangement.

- Each tier shall be completely dismantled and the material lowered to the ground before beginning to dismantle the next tier.

- Dropping of materials shall be avoided to prevent damage to materials and injury to the workmen below.

- A double lanyard safety harness shall be anchored to a strong structure or lifeline before attempting to loosen stuck or jammed parts is essential.

- At the end of the day, if a scaffold is going to be left half dismantled, it is essential to lower all the loose scaffold materials down and ensure that the scaffold is braced adequately to the building/structure.

- All the dismantled materials shall be stacked in the appropriate manner at the designated place.

Working Platform:

- A working platform shall be designed to support the weight of the personnel and equipment to be used.

- Working platform shall be fully decked with scaffold boards.

- Scaffold boards should be secured to prevent displacement.

- Working platform shall be erected on stable scaffold.

- Every working platform shall be provided with a ladder or any other safe means of access.

- Edges of the platform shall be provided with guardrail. Height of the top rail shall be from 900 – 1200 mm. the mid rail shall be provided halfway between the platform and the top rail on the inside of the posts. Toe guard shall be of minimum 100 mm height.

- Posts and rails shall be capable of withstanding a force of at least 900 N (22 lb) applied at any point, or withstanding any load likely to be applied.

- Barriers shall be provided on open edges, holes and openings of the platform.

- The minimum width of working platform shall be as follows: 1. Only workmen – 600 mm. 2. men, tools and materials – 900 mm. 3. men, tools, materials and wheel barrows – 1200 mm.

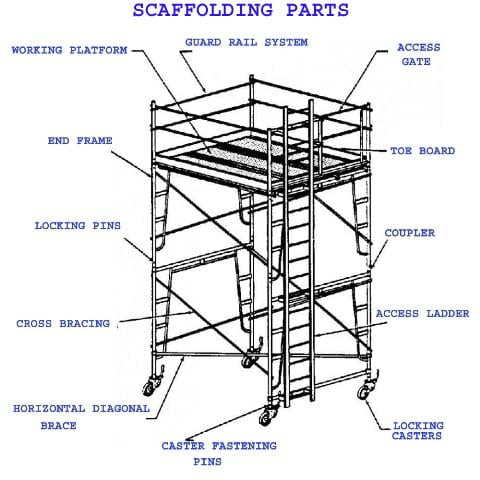

Scaffolding Components:

- Sole plate

- Base plate

- Standards

- Ledgers

- Bracing

- Decking

- Guard rails (Hand rails and mid-rails) height approximately 1 meter.

- Toe board should be minimum 6 inches in height.

- The ladder shall be secure at three locations.

- Tags either green or red tag and shall be renewed after one week.

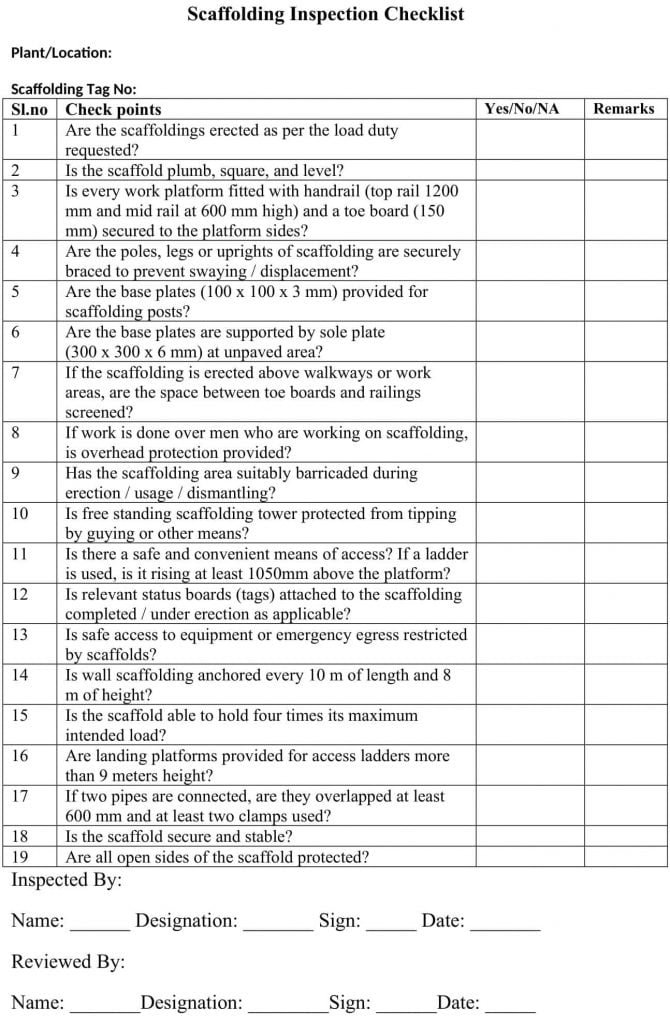

Scaffolding Inspection

- Regular inspection is required to ensure the stability, strength and safety of scaffolds.

- The scaffolding should be inspected by a competent person.

- Inspect before starting the use of scaffold.

- Inspect every week during use.

- Inspect after heavy rains and storms.

- Inspect at any time when comptent person feel it necessary.

- The scaffolding must be inspected as per the inspection checklist.

- Scaffolding inspection tags must be availabe at work site.

- Scaffolding was erected under supervision.

Scaffolding Inspection checklist

Scaffolding Hazards:

- Unsecured ladder slipping.

- Use of unsuitable, damage and faulty materials.

- Inadequately supported scaffold boards.

- Omission/removal of guard rails.

- Not proper tie-in/braced.

- Overloading of platform and board.