Noise may be defined as the undesirable sound that interferes significantly with the comfort, health, or welfare of persons or with the full use or enjoyment of property. Sound is produced by the vibration of an object or mechanism and transmitted in the form of waves. It is a special kind of wave action usually transmitted by air, in the form of pressure waves, and received by the hearing apparatus (ear) in the body of human beings and animals.

Decibel (dB) is the unit of sound level measurement. A Decibel (one-tenth of a bel) is a physical unit based on the weakest sound that can be detected by the human ear. It is named after Alexander Graham Bell, the inventor of the telephone.

Table of Contents

Generation of Noise:

Sound is an acoustic vibration generated due to the movement of particles of an elastic medium (e.g. air, liquid, metal). Sound produces an auditory sensation between 16 Hz to 20000 Hz frequency range. Physicians define noise as a superposition of sounds of different frequencies and intensities without any phase correlation. Physiologists consider noise as any unpleasant or disturbing sound. Environmental noise is a noise of measurable intensity such as is normally noticed in workplaces.

The sound wave is generated when an object vibrates in the air (or another medium) and the disturbed air particles spread away from the object in the form of a wave.

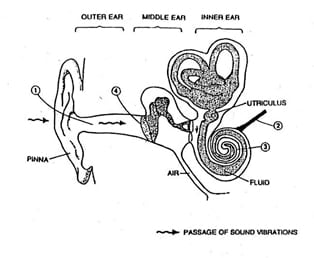

These waves in turn impinge on our eardrum and set it in vibration. Moving fluid and thousands of hair cells inside the car convert the vibrations into nerve impulses which are carried to the brain where the impulses are converted (interpreted) into what we hear as sound.

Causes of noise:

- The causes of noise may be stationary or mobile. The sources of noise are more in urban and industrial areas than in rural areas.

- The stationary noise pollution sources includes industries, use of loud speakers on various occasions, worships in temples and mosques etc., house hold gadgets like vacuum cleaner, T.V., radio, stereo, grinder, mixer etc., common vegetable and fish markets etc. the mobile noise pollution sources include road traffic, railway traffic, air traffic etc.

Classification of sources of noise

- Transportation / Traffic noise

- Industrial noise

- Noise from construction work.

- Neighborhood noise.

Noise from various vehicle type

| SL.NO. | VEHICLE TYPE | NOISE (dB) |

| 1 | Luxury cars | 77 |

| 2 | Small passenger cars | 79 |

| 3 | Miniature passenger cars | 84 |

| 4 | Sports car | 91 |

| 5 | Motor cycle | 94 |

| 6 | Scooter | 80 |

Noise:

- inharmonious sound surveys are necessary in all industries / ports areas where the current limit of 90dB (A) may be exceeded. Measurements have to be made to obtain a fair representation of the noise to which employees are subjected.

- Measurement of sound has two bases

- Frequency – measured in Hertz (Hz)

- Intensity – measured in decibels (dB)

- The unit of noise is bel, which is too great for the human ear. Hence the ‘bel’ is divided into 10 parts, i.e. decibel (dB). The limit of noise is 80 to 90 dB.

The intensity level of some familiar sounds are:

| 1 | Jet aircraft | 150 dB |

| 2 | Hydraulic press | 130 dB |

| 3 | Loud thunder | 120 dB |

| 4 | Riveting or press work | 110 dB |

| 5 | Subway train | 100 dB |

| 6 | Heavy traffic | 80 dB |

| 7 | Machine shop | 80 dB |

| 8 | Normal conversation | 60 dB |

| 9 | Quiet running car | 50 dB |

| 10 | Office | 40 dB |

| 11 | Tick of watch | 30 dB |

| 12 | Whisper | 20 dB |

| 13 | Leaves in wind | 10 dB |

Continuous and impulse noise:

- Sound or inharmonious sound is continuous when the source is constantly vibrating, e.g., motorized bell.

- It may be impulsive when the source causes vibration only for a short time e.g. sound from a drop forge hammer, explosion or a rifle shot.

- Third category of sound is classified as fluctuating sound. In a large workshop where numbers of machines are in operation, noise level varies from time to time. As a result the inharmonious sound pattern produced through out the day is plotted. Then equivalent continuous level should be measured as a mean fluctuating level.

Four methods of noise reduction:

- Reduction of noise at source.

- Isolation of equipments.

- Absorption of noise.

- Using ear plugs and ear muffs.

The effect of noise on man:

- Sleep disturbance and stress reactions.

- Increased blood pressure.

- Blood cholesterol and sugar.

- Gastric problems.

- Behavioral effects.

- Fatigue.

- Mental health effects – neurosis.

- People working in noisy area (foundry) suffer with neurological and psychiatric difficulties.

- Abnormal heart rhythms – steel industry.

- High BP – in fabrication industry.

- Noise – an industrial health enemy and inevitable in modern industry.

- Any sound which is dangerous to our precious hearing is called noise.

- Hearing loss is gradual – becomes severe over a period of years. Once developed it is non curable. Hearing loss is a noticeable disease in a plant and compensable under Factories Act.

- To avoid noise loss compensable disease hearing conservation program (HCP) are:

- Noise measurement.

- Noise control.

- Hearing testing.

- Education.

Noise measurements:

- Measurements by noise level meter TLV of noise – 90 dB for eight hours:

| The intensity of level dBA | Allowable exposure duration in hours |

| 90 | 8 |

| 95 | 4 |

| 100 | 2 |

| 105 | 2 |

| 110 | ½ |

| 115 | ¼ |

Beyond 115 dBA nobody should be allowed to work. More than 90 dBA reducing methods are required.

- The methods of reducing the noise:

- Engineering controls.

- Administrative control.

- Personal protective equipments.

- Engineering controls:

- Maintenance of machine.

- Substitution of machine.

- Substitution of process.

- Vibration control of driving force.

- Reducing sound transmission through solids.

- Reducing sound produced by fluid flow.

- Reduced noise by transmission of air.

- Isolating the operator.

2.Administrative controls:

If the noise level is more than 100 dB workers may be rotated every two hours.

3.Use of PPE:

Must be the second choice. When engineering methods fail Earplugs and Earmuffs may be used.

| Earplug | Earmuff |

| Suitability of ear. | Fits all. |

| Training is required to use the plug. | No training is required. |

| Maintenance daily cleaning after use. | Easy to check the wearer from distance. |

Perception of Noise :

It is the human ear that perceives or hears the sound and sends the message to the brain through the senses.

The ear has 3 parts – the outer ear, the middle ear, and the inner ear. The outer ear contains the external auditory canal which carries sound waves to the eardrum (tympanic membrane). The middle ear has an eardrum and hammer which vibrate due to sound waves. This assembly transmits sound waves to the inner ear after amplifying or diminishing the sound to protect the inner ear, thus regulating the sound level. Two muscles tighten the eardrum and give acoustic reflex as per the brain’s command. Due to high noise or many years o) hearing, these muscles weaken resulting in hearing loss. The inner ear is a complex system of bony fluid-filled crevices and is responsible for our sense It sends messages to the brain.

Nature and Characteristics of Noise–

Noise or inharmonious sound is a sound but it is an unwanted or undesired sound i.e. a sound without agreeable musical quality. It is an annoyance and interferes with work efficiency and causes accidents, hearing loss, or deafness depending upon its type and period of exposure. Glorying and Wheeler’s study show that the greater the length of exposure, the is the degree of hearing loss, especially in 4000 to 8000 c/s frequency.

Sudden and loud inharmonious sound produces high reactions in all persons and loud and persistent noise (of high pitch) may produce deafness. Such noise should be eliminated if possible, otherwise, avoided by ear protection.

Frequency:

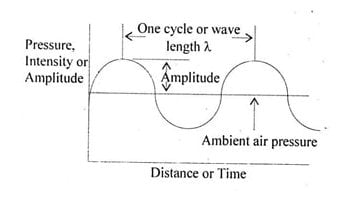

It is the number of pressure variations (vibrations) above and below atmospheric pressure (760 mm of Hg) i.e. the rate at which complete cycles of high and low-pressure regions are produced by sound sources. Its unit is cycles/sec or Hertz (Hz). Normally human ear registers frequencies from 2020000 Hz. This is known as the audible range of frequencies. Frequencies below 20 Hz are called infrasonic and above 20000 are called ultrasonic. The ear is most sensitive between 1000 to 4000 Hz and damage occurs above 4000 Hz. The instrument used to measure sound frequency is known as an octave band analyzer.

Wavelength:

The distance required to complete one cycle of pressure is called one wavelength (X) or a distance between two crests or troughs of the wave.

Wavelength (λ) = Speed of sound (S) /Frequency (F) (where speed of sound = 344 m/s or 1130 ft/sec.)

Period:

It is the time required to complete one pressure cycle and is reciprocal of the frequency. It is measured in seconds (T).

Sound Intensity (I) or Amplitude:

It determines the loudness (though both are not the same) and is measured in terms of decibels (dB). At a specific location, the sound intensity is the average rate at which sound energy is transmitted through a unit area normal to the direction of sound propagation.

Intensity is the pressure or energy that the shunted air particles deliver to an ear. It falls off with distance and is given by the decibel or dB which tells us how many times bigger the intensity of a particular sound is than the intensity of the reference sound at the bottom of the scale. ‘dBA’ refers to the sound level in decibels as measured on a sound level meter operating on a – weighing network (reference) with slow meter response.

Hearing Testing:

Hearing testing is done to monitor the Hearing status of the worker. Few people get hearing loss even at a low level due to individual susceptibility. Hearing testing – every 12 months- Audio-metrically. Pre-employment testing is important. Workers are to be educated about the noise.

Noise control methods

| Noise control methods | At path | At receiver |

| Substitution Isolation Segregation Relocation Redesign Selection of m/c & method Enclosures Barriers Reducing energy or forces of damping. | Absorption Barrier Silencer Soundproofing vibration-damping Remote control and isolation. | Ear protection (plugs and muffs) Medical supervision and audio-graphic reduction in exposure time. Isolating workers by a booth changing job schedules giving rest intervals. |

Control at source:

- Much noise can be eliminated by good engineering design.

- Wire mesh screens instead of sheet metal panels reduce vibrating noisy surfaces.

- Lining of absorbent materials would also reduce noise considerably.

- Machines can be mounted on rubber or other materials so that vibration and noise or inharmonious sound will be reduced.

- Proper lubrication, tuning and well maintained equipment produce less noise.

Substitution of less noisy processes:

- Welding instead of riveting

- Mechanical forging instead of drop forging

- Grinding instead of chipping

- Belt drive instead of gears

- Hydraulic riveting instead of pneumatic riveting

- Mechanical ejectors instead of air ejectors

- Slow acting process instead of high speed

- Hot working of metal instead of cold working

- Presses instead of hammers

- Rotating shears instead of square shears.

- Pressing instead of rolling or forging.

Segregation and isolation:

- Noisy machines are removed to an area where few people work (segregation).

- Well insulated partition and tightly closing doors may be installed surrounding the machines (isolation).

- Providing a sound proof booth for the operator, separate location of noisy machines and processes from quiet ones e.g. air compressor or diesel generator rooms should be separate and away from library, training center, conference room, medical center etc.

- Office space should be segregated from the production area.

- Equally noisy areas should be located together and segregated from quiet areas by buffer zones that can tolerate intermediate noise levels.

- Reflected sounds from ceiling and walls can be reduced by hanging isolators made of rubber, felt or cork.

Enclosure of noise source:

- Sound proofing by barrier structures.

- More surface area of enclosure will reduce more noise.

- Barrier wall facing the noise source should be coated with acoustic absorption material on that side to reduce noise appreciably.

- Double wall with 10 cm intervening space is more effective than single partition of the same height.

- Porous materials (e.g. porous concrete) can absorb more sound than rigid material.

Sound absorption (Acoustic Insulation):

- High frequency sound can be absorbed by applying sound absorbents to ceiling and walls in the form of acoustical tiles, plasters and blankets of precious materials such as glass wool. Acoustic baffles can be hung from the ceilings. This can reduce 3 to 8 dB noise level.

- A variety of absorbent materials are available for an acoustic engineer in the form of vegetable or asbestos fibers, glass or mineral wool and hard but porous plaster having less susceptibility to physical damage, fire resistance, light reflection, aesthetic qualities etc.

Silencers:

- Silencers are one type of sound absorbers. The velocity and pressure of air get reduced when it is routed through devious paths in the muffler components.

- The mufflers are of two types. In absorptive or, dissipative type a lining of absorptive material is provided and is protected by a perforated metal cover.

- The absorptive silencers has better performance at higher frequencies where as the reactive type at low frequencies. Sound reduction or insertion loss increases with length, thicker splitters and reduced air gap.

Sound proofing:

- Sound proofing includes construction or barrier structures such as walls or partitions, to safeguard the workers from external inharmonious sound.

- Sound proofing utilizes the principle of reflection of sound i.e. the greater part of sound energy incident on a surface is reflected and only its’ smallest part (1/1000 or less) penetrates through it.

- In sound proofing following factors are required to be considered for obtaining desired results:

- Intensity of sound.

- Frequency of sound.

- Co-efficient of absorbency of material used for sound barriers.

Ear Protection :

Personal protection should be used as a last resort. Earplugs, earmuffs, and helmets can be used by the exposed person for attenuation of noise to a safe level. Where noise or inharmonious sound levels are very high, better attenuation can be obtained by using both earplugs and earmuffs.

If properly selected and used, personal protective equipment and devices, such as sound-proof head-sets (helmets), earmuffs, earplugs, and noise stoppers can afford effective protection against inharmonious sound disturbances and prevent various functional disorders. To the extent that accidents and hearing loss may result from exposure to excessive noise, these devices are a preventive measure and can be used in addition to the principal noise control, measures when they are found ineffective.

Earplugs or defenders are the simplest, cheap, and convenient devices used to reduce the harmful effect of noise. They are conical-shaped plugs of various materials for insertion into the ear to reduce the perception of noise, particularly impulse inharmonious sound. They can be soft or rigid. Rigid plugs are made of rubber or plastic materials while soft plugs are of cotton cloth or of very fine glass cloth impregnated with oil or a waxy mastic. Plugs do not prevent the wearer from wearing headpieces or goggles. However, during long use, ear defenders may cause discomfort and irritation in the ear, particularly at elevated temperatures. The application of multi-use ear defenders requires special medical supervision.

Earmuffs are large pads of rubber or similar material attached to a band or strap and worn about the head for reducing the effect of noise on factory workers (during impact riveting, straightening, chopping, and the like operations). The device is light, convenient to wear, and effective against the inharmonious sound of high frequency which is exclusively harmful to the human ear.

Hearing protective devices are classified into four groups:

- Enclosures (entire head) e.g. helmet.

- Aural inserts e.g. earplugs – formable, custommoulded & remoulded type.

- Super aural protectors – A soft rubber like material is held and inserted in the external ear canal. Band tension holds it inside (ear plugs).

- Circum aural protectors e.g. earmuffs. Two cups are held by a spring-loaded suspension assembly or headband.