The Dow Fire and Explosion Index (F&EI) is generally used in evaluating the hazard category of a process plant, area of exposure, expected losses in case of fire and explosion, etc. The hazard classification guide was developed by Dow Chemical Company. Published by the American Institute of Chemical Engineering, Dow (1994). Dow Fire and explosion index (DOW F&EI) gives a method of evaluating the potential risk from the process and assessing the potential loss.

Table of Contents

Objectives of dow fire and explosion index

Quantify:

The expected damage potential due to fire & explosion incidents in realistic terms.

Identify:

Equipment that is likely to contribute to the creation or escalation of an incident.

Communicate:

The fire & explosion potential, to design teams and also the plant personnel.

- It is tailored for the storage, handling, and processing of explosive and flammable material in the chemical process industry.

- It uses a systematic approach based on the rating form.

- Suitable to be used at an early stage of a project and for auditing the existing plant.

- The final rating number (ie F&EI) provides a relative ranking of hazards.

- It is also used for estimating damage radius (using Dow correlation) and estimate the financial loss in the event of an accident (using consequence analysis form).

When should one perform dow fire and explosion index?

- Late in the Phase III Engineering after:

- P&IDs has been completed,

- The equipment has been sized,

- A trial equipment layout has been prepared.

- A DFC estimate has been prepared.

Who usually performs the dow fire and explosion index

- Generally, a senior process engineer, who is acquainted with the details of the project, is assigned this task.

- Occasionally, different groups are asked to tackle these assignments and their results are compared for a consensus-building.

General process hazard

•The general process hazards are factors that play a primary role in determining the magnitude of the loss following an incident.

- Exothermic chemical reaction

- Endothermic processes

- Materials handling and transfer

- Access to emergency equipment

- Drainage and spill control

Special process hazards

The special process hazards are factors that are known from experience to contribute to the probability of an incident involving loss.

- Due to Toxic materials

- Sub-atmospheric pressure

- Operation in or near flammable range

- Dust explosion Leakages

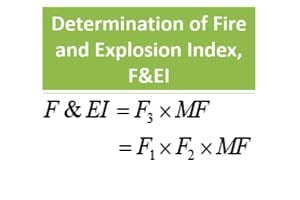

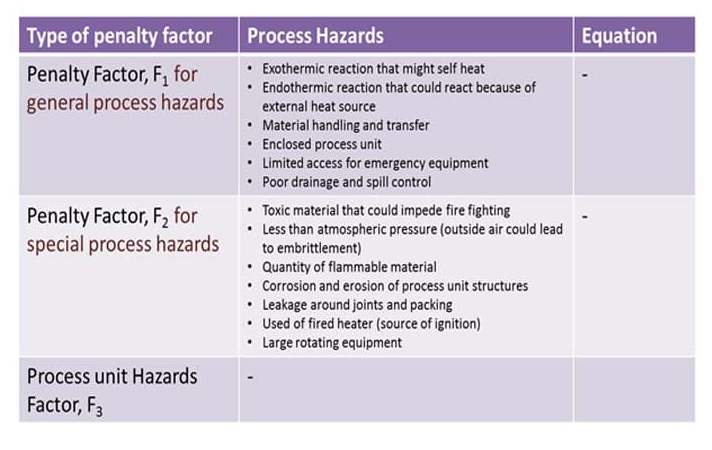

Parameter in dow fire and explosion index

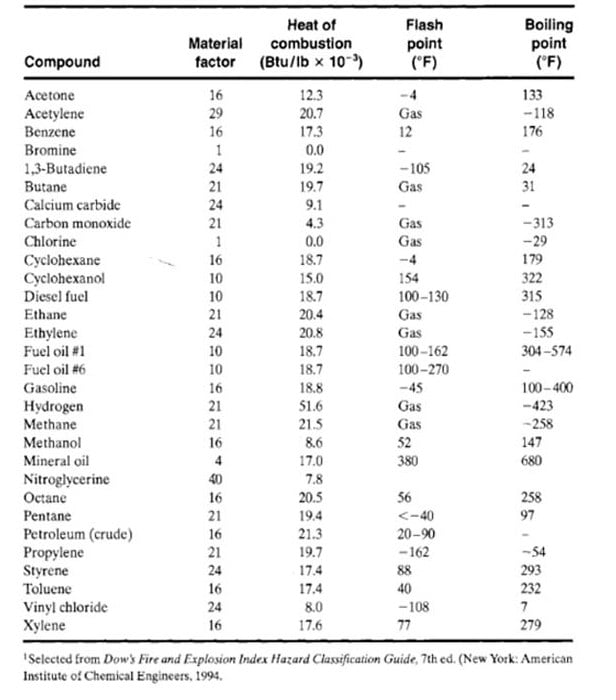

- Material Factor (MF)

- The measure of Reactivity and Flammability

- General Process Hazards (F1)

- Plays a primary role in determining the magnitude of loss in an incident

- Special Process Hazards (F2)

- Indicates the probability of loss in an incident.

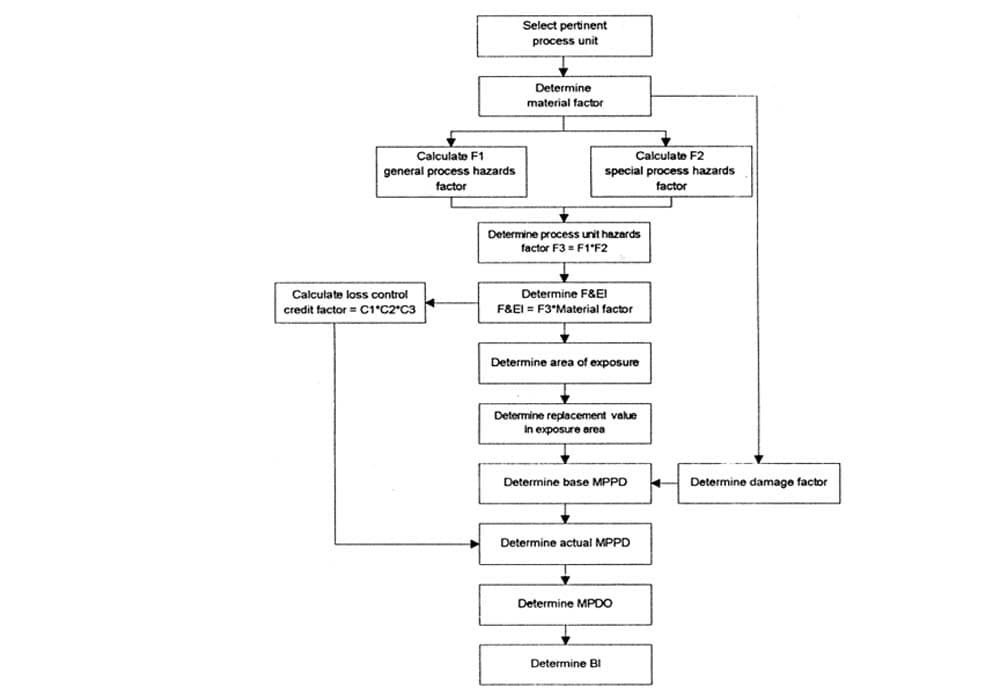

Loss control credits (lccf)

Are features that have proved beneficial in preventing serious incidents and reducing the magnitude of a particular incident.

- Process Control.

- Material Isolation.

- Fire Protection.

Maximum Probable Property Damage (MPPD)

Represents the property damage that could result from an incident of reasonable magnitude with adequate functioning of protective equipment.

Maximum Probable Days Outage (MPDO)

Time is required to rebuild the plant to its original capacity.

Business Interruption (BI)

The loss of profit to the company due to an incident.

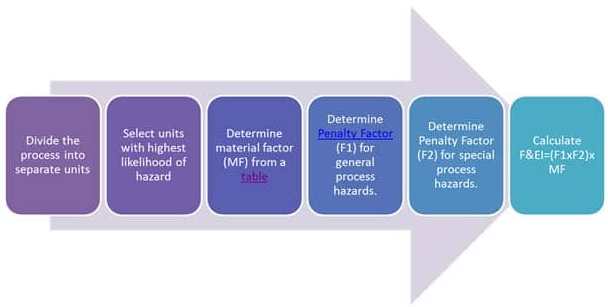

Procedure for calculating dow fire and explosion index

Simplified procedure for calculating dow F&EI–

Determination of material factor–

Penalty factors–

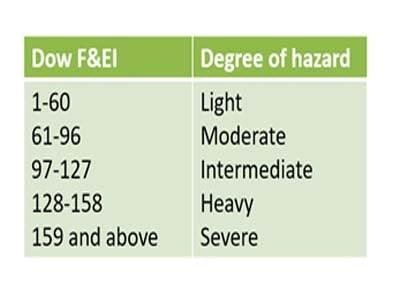

Degree of hazard from the dow fire and explosion index–