The main goal of industrial safety is to prevent workplace accidents, injuries, illness, or death. Before we know about industrial safety let us know what is safety.

Safety is a condition that gives you freedom from hazards, risks, and accidents that may cause injury, damage, loss of material or property damage, and even death. In its simplest form Elimination of hazards is also known as safety. (The condition or state of being safe, freedom from danger or hazard, exemption from hurt, injury, or loss).

Table of Contents

What is Industrial Safety?

Industrial safety is primarily a management activity that is concerned with reducing, controlling, and eliminating hazards from the industries or industrial units. ( Industrial safety is defined as policies and protections put in place to ensure plant and factory worker protection from hazards that could cause injury).

Safety is a basic need in any industry. The workplace safety program creates a positive atmosphere and it may help to improve workers’ morale.

Safety must always be the primary concern for industrial facilities, from protecting employees from accidental injuries to protecting equipment from serious damage, which in turn may result in costly downtime and repairs.

What is Industrial safety management?

Industrial safety management is a section of management It includes the managerial function of the Establishment of objectives, and the Process of planning, organizing, controlling, and directing to reduce or eliminate industrial mishaps, and also, encourage workers to work safely.

Safety plays a vital role in the industry by protecting employees and assets by minimizing hazards, risks, accidents, and near misses.

Why industrial safety is important?

- The basic need for safety in industry or any other field is to prevent the occurrence of mishaps and hazards that sometimes cause heavy loss of life, property, and the environment.

- Each and every employee in the industry desires to work in a safe and protected atmosphere and it is the moral responsibility of the industry to look toward employee protection.

- Every year millions of industrial accidents occur which result in a loss of production time equivalent to the loss of millions of man and machine hours.

- A serious workplace injury or death changes lives forever for families, friends, and co-workers. Human loss and suffering are immeasurable and intolerable which is why it is necessary to maintain industrial safety.

- Safety is important for protecting the environment against damage from industrial accidents and also for minimizing financial losses, property damage, accidents, injury, and even death.

Why Emergency Preparedness is important in any industry?

Industrial safety goes beyond accident prevention; it also involves being prepared for emergencies. Evacuation plans, first aid kits, and well-defined emergency procedures are crucial.

Industrial safety topics:

- General Safety

- Occupational Health and Safety

- Process Safety

- Material Safety Datasheet

- Workplace Safety

- Fire Safety

- Electrical Safety

- construction safety

- Ergonomics Safety

- Working at height safety

- Chemical safety

- Radiation Safety

- Environmental Safety

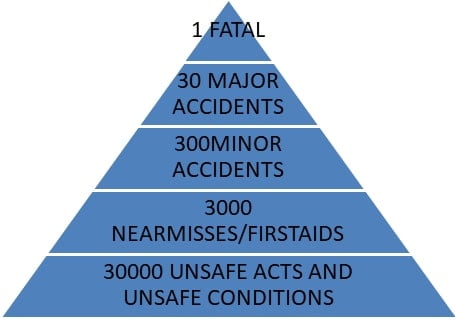

Hazard Pyramid:

Since 30,000 unsafe acts and unsafe conditions caused 3000 near misses or first-aid. 3000 near misses cause 300 minor accidents, 300 minor accident causes 30 major accidents and 30 major accident causes 1 fatal. So it is very important to stop the creation of unsafe acts and unsafe conditions.

12 steps of full safety in the industry:

- Hazard analysis

- Use of PPE(Personal protective equipment)

- Use of sop (Standard operating procedure)

- Positive isolation

- Work permit system

- Gas safety

- Right tools and tackles

- Confined space permit

- Working at height

- Traffic rules

- Safety in multi-activities

- Change management.

Some life-saving rules in the industry:

- Working under the influence of alcohol or illegal drugs

- Non-compliance to the rule of confined space

- Starting the job without a work permit /clearance

- Non-fulfillment of conditions essential to ensure safe welding and gas cutting.

- Tempering of locks in positive isolation.

Accident prevention methods:

- 5 e’s for accident prevention

- Preventing unsafe acts

- Preventing unsafe conditions

- Safety tag system

- Safety in hose keeping

- Employees’ training in safety

- Hazard checklist

- Color coding

- Motivating employees for safety

- Safety Auditing

5 e’s for accident prevention:

- Engineering

- Education

- Enforcement

- Enthusiasm

- Evaluation

How to develop a safety culture:

- Management safety policy

- Total loss control management.

- Accident investigation.

- Plant and facility inspection.

- Statutory laws and standards.

- Safety committee meeting.

- Group meeting management.

- General safety promotion (posters, banners, signs, etc.)

- Personal protection.

- Supervisory training.

- Employee training.

- Selection and employment procedures.

- Reference library.

- Occupational health and hygiene.

- Fire prevention and loss control.

- Accident analysis.

- Personal safety communications.

- Job safety analysis (JSA)

- job safety Observations (JSO).

- Records and statistics.

- Emergency care.

- Product liability.

- Off-the-job safety.

- Incident recall and analysis.

- Traffic safety/transport.

- Security facility.

- Ergonomic application.

- Pollution and disaster control.

Safety Terminologies:

What is Nearmiss?

A near miss is an unplanned event that did not result in injury, illness, or damage but had the potential to do so.

What is Firstaid?

First aid is immediate skilled assistance given to the victim by a certified first aider in case of an accident, injury, or illness before medical aid is available.

What is Risk?

Risk is the combination of the likelihood and consequence of a specific hazard event occurring (R=L*C).

What is an injury?

Injury is physical harm or damage to the body resulting from an exchange of (usually acute, mechanical, chemical, thermal, or other environmental) energy that exceeds the body’s tolerance.

What is Disabling Injury?

Disabling injury is an injury causing death, permanent disability, or any degree of temporary total disability beyond the day of the injury.

What is an accident?

It is an unexpected or unplanned event that may or may not result in injury damage property loss or death.

What is personal protective equipment?

It is the equipment used to protect the person from hazards such as dust, dirt, fumes, sparks, etc. It is the barrier between hazard and person.

What does OSHA stand for?

OSHA stands for the Occupational Safety and Health Administration. This federal agency operates under the United States Department of Labor, with a primary objective of ensuring safe and healthy working conditions for employees.

OSHA came into existence on April 28, 1971, when President Richard Nixon signed the Occupational Safety and Health Act into law.

OSHA’s Mission:

OSHA is dedicated to its mission of saving lives, preventing injuries, and protecting the health of America’s workers. To achieve this mission, OSHA has established a comprehensive framework.

OSHA Regulations:

Occupational Safety:

OSHA sets forth regulations that cover a wide range of occupational safety aspects, such as the proper use of personal protective equipment, machinery safety, and fire prevention measures.

Health Standards:

OSHA also enforces health standards that address issues like exposure to hazardous chemicals, air quality, and noise levels in the workplace.

Conclusion:

Industrial safety is not an option; it’s a necessity for protecting lives and assets. Embracing a safety-first culture, adhering to regulations, investing in technology, and continuous improvement are keys to a safer and more productive industrial future.

Faqs for industrial safety?

What is an incident?

Any event that could result in:

1. Injury and illness.

2. Property damage.

3. Environmental release.

4. Business interruption etc.

What is the hazard?

Any real or potential condition that can cause injury, illness, or death to personnel, damage to or loss of a system, equipment, or property, or damage to the environment.

For example, workers could be electrocuted by touching exposed contacts in an electrical panel containing high voltage.

What is a mishap?

An unplanned event or series of events resulting in death, injury, occupational illness, damage to or loss of equipment or property, or damage to the environment.

For example, workers were electrocuted by touching exposed contacts in an electrical panel containing high voltage.

What is industrial safety?

In the dynamic world of industry and manufacturing, ensuring the safety of workers and protecting valuable assets is paramount. Industrial safety not only safeguards lives but also plays a pivotal role in maintaining productivity and profitability.

What are the 4 types of industrial safety hazards?

1. Fire Hazard.

2. Chemical Hazard.

3. Fall From Height.

4. Electrical Hazard, etc.

What are the 5s in safety?

1. sort

2. set in order

3. shine

4. standardize and

5. sustain

What does OSHA stand for?

OSHA stands for the Occupational Safety and Health Administration. This federal agency operates under the United States Department of Labor.

Related posts:

- What is the hazard?

- What is Hazop?

- Duties of a safety officer.

- What is hazard identification?

- What is the hazard triangle?

- Power tools safety.

- Hand tool safety.

- What is an unsafe act?

- What is an unsafe condition?